| Encapsulation Solder ntawm Diode Laser Bar Stacks | Ntim AuSn |

| Nruab Nrab Wavelength | 1064nm |

| Lub zog tso zis | ≥55W |

| Ua Haujlwm Tam Sim No | ≤30 A |

| Ua Haujlwm Voltage | ≤24V |

| Hom Ua Haujlwm | CW |

| Qhov ntev ntawm qhov cavity | 900 hli |

| Daim iav tso zis | T = 20% |

| Kub ntawm dej | 25 ± 3 ℃ |

Sau npe rau peb cov social media kom tau txais cov ntawv tshaj tawm sai

Qhov kev thov rau CW (Continuous Wave) diode-pumped laser modules tab tom nce ntxiv sai sai ua qhov tseem ceeb ntawm kev siv cov lasers solid-state. Cov modules no muaj cov txiaj ntsig tshwj xeeb los ua kom tau raws li cov kev xav tau tshwj xeeb ntawm cov ntawv thov laser solid-state. G2 - A Diode Pump Solid State Laser, cov khoom tshiab ntawm CW Diode Pump Series los ntawm LumiSpot Tech, muaj thaj chaw siv dav dua thiab muaj peev xwm ua tau zoo dua.

Hauv tsab xov xwm no, peb yuav muab cov ntsiab lus tsom mus rau cov ntawv thov khoom, cov yam ntxwv ntawm cov khoom, thiab cov txiaj ntsig ntawm cov khoom hais txog CW diode twj tso kua mis solid-state laser. Thaum kawg ntawm tsab xov xwm, kuv yuav ua qauv qhia daim ntawv qhia kev sim ntawm CW DPL los ntawm Lumispot Tech thiab peb cov txiaj ntsig tshwj xeeb.

Daim Ntawv Thov

Cov laser semiconductor muaj zog heev feem ntau yog siv ua cov twj tso kua mis rau cov laser solid-state. Hauv kev siv tiag tiag, qhov chaw twj tso kua mis semiconductor laser diode yog qhov tseem ceeb rau kev ua kom zoo dua ntawm cov thev naus laus zis laser diode-pumped solid-state.

Hom laser no siv lub semiconductor laser nrog lub zog tso zis ruaj khov es tsis txhob siv lub teeb Krypton lossis Xenon ib txwm los tso cov siv lead ua. Yog li ntawd, lub laser hloov kho tshiab no hu ua 2ndtiam ntawm CW twj tso kua mis laser (G2-A), uas muaj cov yam ntxwv ntawm kev ua haujlwm siab, lub neej ntev kev pabcuam, zoo beam zoo, zoo stability, compactness thiab miniaturization.

Muaj peev xwm nqus dej muaj zog heev

CW Diode Twj Tso Kua Muaj Zog Ntau, Ua Kom Tau Txais Qhov Nruab Nrab Hauv Lub Laser Khob, Kom Tau Txais Kev Ua Haujlwm Zoo Tshaj Plaws Ntawm Lub Laser Khob. Tsis tas li ntawd, nws lub zog siab tshaj plaws (lossis lub zog nruab nrab) ua rau muaj ntau yam kev siv hauvkev lag luam, kev kho mob, thiab kev tshawb fawb.

Zoo heev Beam thiab stability

CW semiconductor pumping laser module muaj qhov zoo tshaj plaws ntawm lub teeb ci, nrog kev ruaj khov yam tsis muaj kev txwv, uas yog qhov tseem ceeb rau kev ua kom tau qhov tso zis laser tseeb. Cov modules no tau tsim los tsim cov qauv teeb pom kev zoo thiab ruaj khov, ua kom ntseeg tau tias kev nqus dej ntawm lub laser khov kho thiab ruaj khov. Qhov feature no ua tau raws li qhov xav tau ntawm kev siv laser hauv kev ua cov khoom siv hauv kev lag luam. txiav laser, thiab R&D.

Kev Ua Haujlwm Nruam Nruam

Hom ua haujlwm CW muab ob qho txiaj ntsig ntawm cov laser wavelength tas mus li thiab Pulsed Laser ua ke. Qhov sib txawv tseem ceeb ntawm CW Laser thiab Pulsed laser yog lub zog tso zis.CW laser, uas tseem hu ua Continuous wave laser, muaj cov yam ntxwv ntawm hom ua haujlwm ruaj khov thiab muaj peev xwm xa ib nthwv dej tas mus li.

Tsim Kom Me Me Thiab Txhim Khu Kev Ntseeg Siab

CW DPL tuaj yeem yooj yim koom ua ke rau hauv qhov tam sim nolaser khov khonyob ntawm seb nws me me thiab muaj cov qauv zoo li cas. Lawv txoj kev tsim kho ruaj khov thiab cov khoom zoo ua kom muaj kev ntseeg siab mus sij hawm ntev, txo cov nqi tsis ua haujlwm thiab kev saib xyuas, uas yog qhov tseem ceeb tshaj plaws hauv kev tsim khoom lag luam thiab cov txheej txheem kho mob.

Kev Xav Tau Ua Lag Luam ntawm Cov Koob ntawm DPL - Cov Kev Lag Luam Loj Hlob

Raws li qhov kev thov rau cov lasers solid-state txuas ntxiv nthuav dav thoob plaws ntau yam lag luam, yog li qhov xav tau rau cov khoom siv twj tso kua mis siab xws li CW diode-pumped laser modules. Cov lag luam xws li kev tsim khoom, kev kho mob, kev tiv thaiv, thiab kev tshawb fawb vam khom cov lasers solid-state rau kev siv precision.

Hauv kev xaus lus, ua lub diode pumping qhov chaw ntawm lub laser solid-state, cov yam ntxwv ntawm cov khoom: muaj peev xwm nqus dej siab, CW hom kev ua haujlwm, zoo heev beam zoo thiab ruaj khov, thiab compact-structured tsim, ua rau kev thov ua lag luam hauv cov laser modules no nce. Ua tus neeg muag khoom, Lumispot Tech kuj siv zog ntau rau kev ua kom zoo dua qhov kev ua tau zoo thiab cov thev naus laus zis siv hauv DPL series.

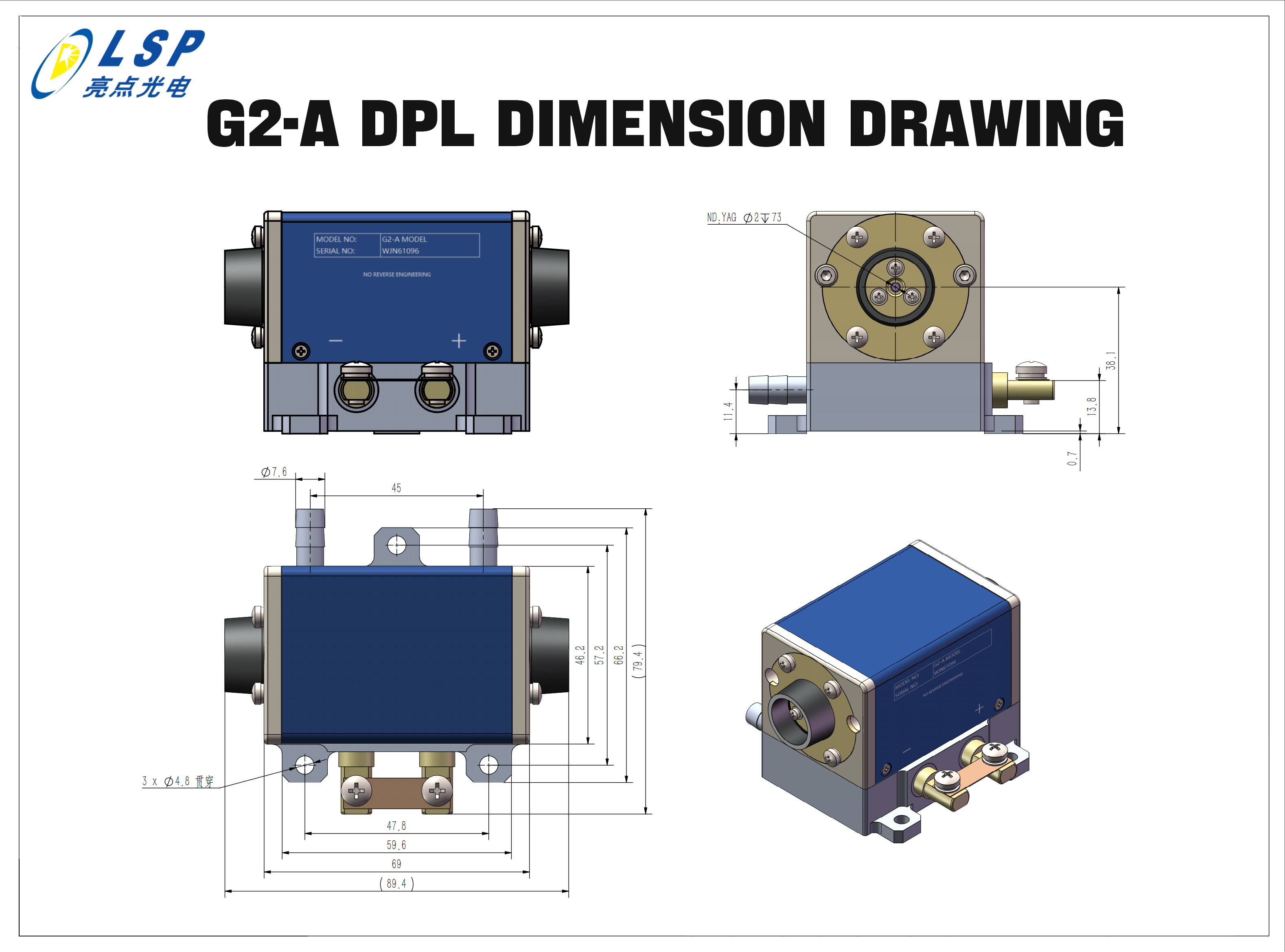

Cov Khoom Siv Ua Ke ntawm G2-A DPL Los Ntawm Lumispot Tech

Txhua pawg khoom muaj peb pawg ntawm cov modules array kab rov tav, txhua pawg ntawm Horizontal Stacked Array modules pumping zog ntawm txog 100W@25A, thiab tag nrho cov zog pumping ntawm 300W@25A.

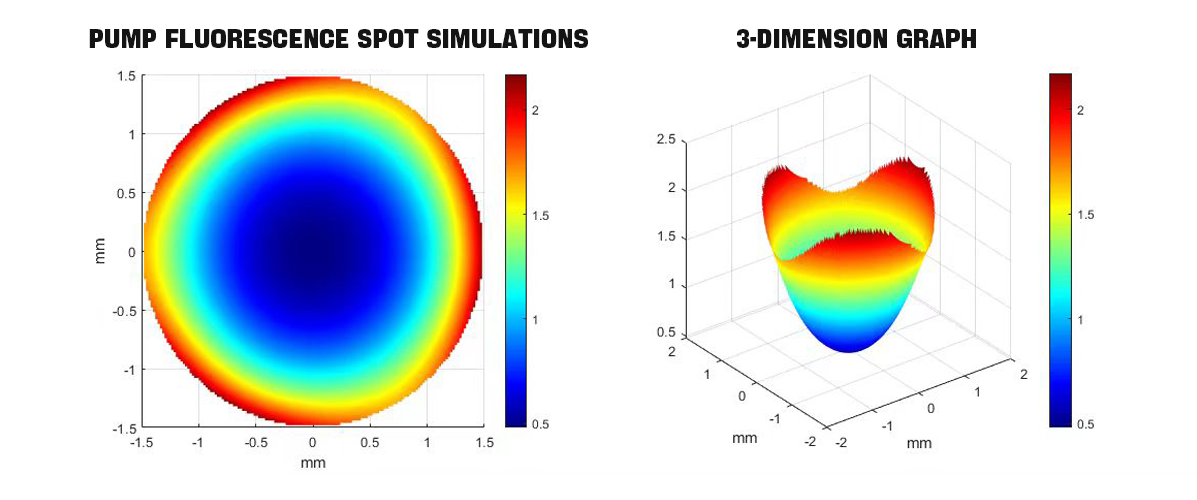

Qhov chaw fluorescence ntawm G2-A twj tso kua mis yog qhia hauv qab no:

Cov Ntaub Ntawv Tseem Ceeb ntawm G2-A Diode Twj Tso Kua Roj Laser:

Peb Lub Zog Hauv Cov Txuj Ci

1. Kev Siv Tshuab Tswj Kub Ib Ntus

Cov lasers semiconductor-pumped solid-state siv dav rau cov ntawv thov quasi-continuous wave (CW) nrog lub zog siab tshaj plaws thiab cov ntawv thov continuous wave (CW) nrog lub zog nruab nrab siab. Hauv cov lasers no, qhov siab ntawm lub dab dej thermal thiab qhov deb ntawm cov chips (piv txwv li, qhov tuab ntawm lub substrate thiab lub chip) cuam tshuam rau lub peev xwm dissipation cua sov ntawm cov khoom. Qhov deb ntawm chip-to-chip loj dua ua rau muaj kev dissipation cua sov zoo dua tab sis ua rau cov khoom ntim ntau ntxiv. Ntawm qhov tod tes, yog tias qhov sib nrug ntawm chip raug txo, qhov loj ntawm cov khoom yuav raug txo, tab sis cov khoom muaj peev xwm dissipation cua sov yuav tsis txaus. Siv qhov ntim me me tshaj plaws los tsim lub laser semiconductor-pumped solid-state zoo tshaj plaws uas ua tau raws li qhov yuav tsum tau dissipation cua sov yog ib txoj haujlwm nyuaj hauv kev tsim.

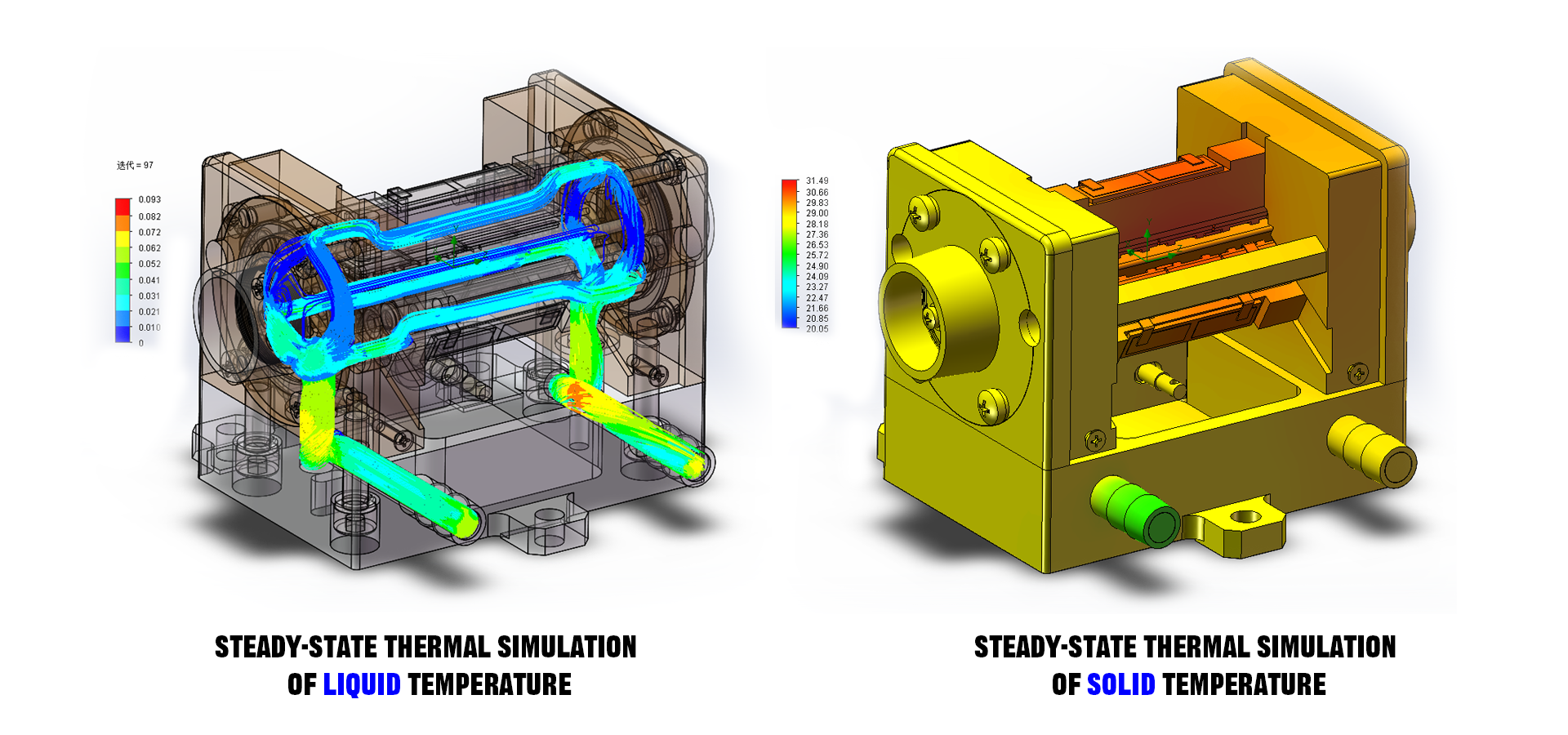

Daim Duab Qhia Txog Kev Simulation Thermal Steady-state

Lumispot Tech siv txoj kev finite element los simulate thiab xam qhov kub ntawm lub cuab yeej. Kev sib xyaw ua ke ntawm kev hloov pauv cua sov khov kho thiab kev simulation kub ntawm cov kua yog siv rau kev simulation thermal. Rau cov xwm txheej ua haujlwm tas mus li, raws li pom hauv daim duab hauv qab no: cov khoom tau hais kom muaj qhov sib nrug zoo tshaj plaws thiab kev npaj nyob rau hauv cov xwm txheej hloov pauv cua sov khov kho. Nyob rau hauv qhov sib nrug thiab cov qauv no, cov khoom muaj peev xwm ua kom sov zoo, qhov kub qis tshaj plaws, thiab tus yam ntxwv me tshaj plaws.

2.AuSn soldertxheej txheem encapsulation

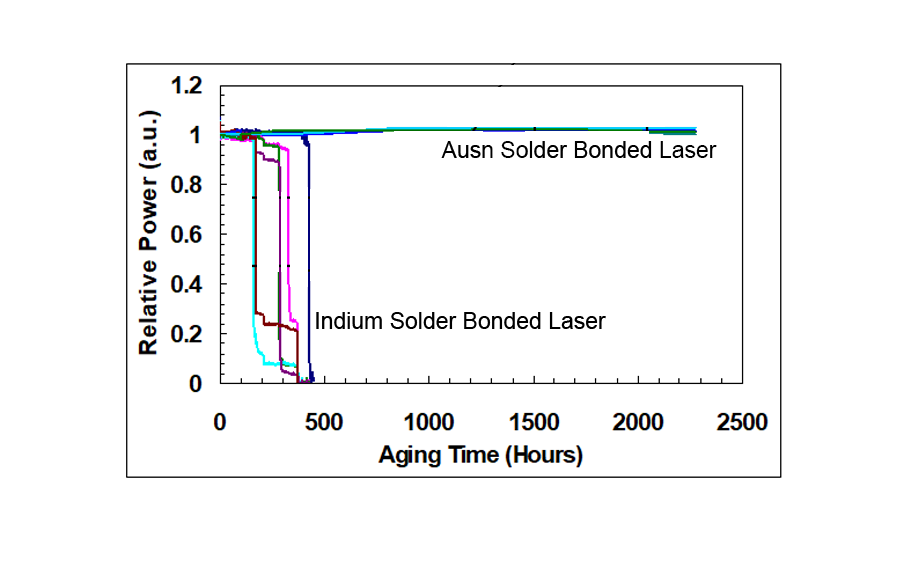

Lumispot Tech siv cov txheej txheem ntim khoom uas siv AnSn solder es tsis siv indium solder ib txwm muaj los daws cov teeb meem ntsig txog kev qaug zog thermal, electromigration, thiab kev hloov pauv hluav taws xob-thermal los ntawm indium solder. Los ntawm kev siv AuSn solder, peb lub tuam txhab lub hom phiaj yog txhim kho kev ntseeg tau ntawm cov khoom thiab lub neej ntev. Qhov kev hloov pauv no yog ua tiav thaum ua kom muaj qhov sib nrug ntawm cov khoom sib dhos, ntxiv rau kev txhim kho kev ntseeg tau ntawm cov khoom thiab lub neej ntev.

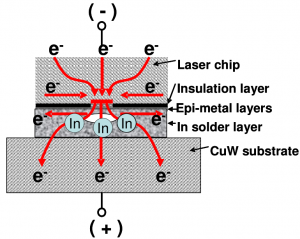

Hauv cov thev naus laus zis ntim khoom ntawm lub zog siab semiconductor pumped solid-state laser, indium (In) hlau tau raug saws los ua cov khoom siv vuam los ntawm ntau lub tuam txhab thoob ntiaj teb vim nws qhov zoo ntawm qhov melting point qis, kev ntxhov siab vuam qis, kev ua haujlwm yooj yim, thiab kev hloov pauv yas zoo thiab infiltration. Txawm li cas los xij, rau semiconductor pumped solid state lasers nyob rau hauv kev ua haujlwm tas mus li, kev ntxhov siab hloov pauv yuav ua rau kev ntxhov siab ntawm indium vuam txheej, uas yuav ua rau cov khoom tsis ua haujlwm. Tshwj xeeb tshaj yog nyob rau hauv qhov kub siab thiab qis thiab ntev pulse dav, qhov tsis ua haujlwm ntawm indium vuam yog qhov pom tseeb heev.

Kev sib piv ntawm kev sim lub neej ceev ntawm lasers nrog cov pob khoom sib txawv

Tom qab 600 teev ntawm kev laus, tag nrho cov khoom encapsulated nrog indium solder tsis ua haujlwm; thaum cov khoom encapsulated nrog kub tin ua haujlwm rau ntau tshaj 2,000 teev nrog yuav luag tsis muaj kev hloov pauv hauv lub zog; qhia txog qhov zoo ntawm AuSn encapsulation.

Yuav kom txhim kho qhov kev ntseeg siab ntawm cov lasers semiconductor muaj zog heev thaum tswj hwm qhov sib xws ntawm ntau yam kev ua tau zoo, Lumispot Tech siv Hard Solder (AuSn) ua ib hom khoom ntim khoom tshiab. Kev siv cov coefficient ntawm thermal expansion matched substrate material (CTE-Matched Submount), kev tso tawm ntawm thermal stress zoo, ib qho kev daws teeb meem zoo rau cov teeb meem kev siv tshuab uas yuav ntsib hauv kev npaj cov hard solder. Ib qho tseem ceeb rau cov khoom siv substrate (submount) kom muaj peev xwm soldered rau lub semiconductor chip yog surface metallization. Surface metallization yog kev tsim ntawm ib txheej ntawm diffusion barrier thiab solder infiltration txheej ntawm qhov chaw ntawm cov khoom siv substrate.

Daim duab kos ntawm lub tshuab electromigration ntawm lub laser encapsulated hauv indium solder

Yuav kom txhim kho qhov kev ntseeg siab ntawm cov lasers semiconductor muaj zog heev thaum tswj hwm qhov sib xws ntawm ntau yam kev ua tau zoo, Lumispot Tech siv Hard Solder (AuSn) ua ib hom khoom ntim khoom tshiab. Kev siv cov coefficient ntawm thermal expansion matched substrate material (CTE-Matched Submount), kev tso tawm ntawm thermal stress zoo, ib qho kev daws teeb meem zoo rau cov teeb meem kev siv tshuab uas yuav ntsib hauv kev npaj cov hard solder. Ib qho tseem ceeb rau cov khoom siv substrate (submount) kom muaj peev xwm soldered rau lub semiconductor chip yog surface metallization. Surface metallization yog kev tsim ntawm ib txheej ntawm diffusion barrier thiab solder infiltration txheej ntawm qhov chaw ntawm cov khoom siv substrate.

Nws lub hom phiaj yog ntawm ib sab tes los thaiv cov solder rau cov khoom siv substrate diffusion, ntawm qhov tod tes yog los txhawb cov solder nrog lub peev xwm vuam khoom siv substrate, los tiv thaiv cov txheej solder ntawm qhov. Kev ua kom zoo nkauj ntawm qhov chaw kuj tseem tuaj yeem tiv thaiv cov khoom siv substrate oxidation thiab cov dej noo nkag mus, txo qhov kev sib cuag hauv cov txheej txheem vuam, thiab yog li txhim kho lub zog vuam thiab kev ntseeg siab ntawm cov khoom. Kev siv cov solder nyuaj AuSn ua cov khoom siv vuam rau semiconductor pumped solid state lasers tuaj yeem tiv thaiv kev ntxhov siab indium, oxidation thiab electro-thermal migration thiab lwm yam tsis zoo, txhim kho qhov kev ntseeg siab ntawm semiconductor lasers nrog rau lub neej ua haujlwm ntawm laser. Kev siv cov thev naus laus zis encapsulation kub-tin tuaj yeem kov yeej cov teeb meem ntawm electromigration thiab electrothermal migration ntawm indium solder.

Kev daws teeb meem los ntawm Lumispot Tech

Hauv cov lasers txuas ntxiv mus lossis pulsed, cov cua sov tsim los ntawm kev nqus ntawm lub twj tso kua mis los ntawm cov laser nruab nrab thiab qhov txias sab nraud ntawm cov nruab nrab ua rau muaj kev faib tawm kub tsis sib xws hauv cov laser nruab nrab, ua rau muaj kev hloov pauv kub, ua rau muaj kev hloov pauv hauv cov ntsuas refractive ntawm cov nruab nrab thiab tom qab ntawd tsim ntau yam teebmeem thermal. Cov thermal deposition hauv cov nruab nrab nce ua rau muaj cov teebmeem thermal lensing thiab thermally induced birefringence nyhuv, uas ua rau muaj qee qhov kev poob hauv lub laser system, cuam tshuam rau kev ruaj khov ntawm lub laser hauv qhov thiab qhov zoo ntawm cov zis beam. Hauv lub laser system khiav tas li, qhov kev ntxhov siab thermal hauv cov zis medium hloov pauv raws li lub zog twj tso kua mis nce. Ntau yam teebmeem thermal hauv lub system cuam tshuam loj heev rau tag nrho lub laser system kom tau txais cov beam zoo dua thiab cov zis muaj zog dua, uas yog ib qho teeb meem uas yuav tsum tau daws. Yuav ua li cas kom zoo inhibit thiab txo qhov thermal nyhuv ntawm cov siv lead ua hauv cov txheej txheem ua haujlwm, cov kws tshawb fawb tau muaj teeb meem ntev, nws tau dhau los ua ib qho ntawm cov chaw tshawb fawb tam sim no.

Nd: YAG laser nrog lub qhov thermal lens

Hauv qhov project ntawm kev tsim cov high-power LD-pumped Nd:YAG lasers, cov Nd:YAG lasers nrog thermal lensing cavity tau daws teeb meem, yog li ntawd lub module tuaj yeem tau txais lub zog siab thaum tau txais lub teeb zoo.

Hauv ib qhov project los tsim ib lub high-power LD-pumped Nd:YAG laser, Lumispot Tech tau tsim lub G2-A module, uas daws tau qhov teeb meem ntawm lub zog qis dua vim yog cov qhov uas muaj thermal lens, uas ua rau lub module tau txais lub zog siab nrog lub teeb ci zoo.

Lub sijhawm tshaj tawm: Lub Xya Hli-24-2023