Sau npe rau peb cov social media kom tau txais cov ntawv tshaj tawm sai

Hauv kev tsim cov khoom siv laser precision, kev tswj hwm ib puag ncig yog qhov tseem ceeb. Rau cov tuam txhab zoo li Lumispot Tech, uas tsom mus rau kev tsim cov lasers zoo, kev ua kom muaj ib puag ncig tsis muaj plua plav tsis yog tsuas yog tus qauv xwb - nws yog kev cog lus rau qhov zoo thiab kev txaus siab ntawm cov neeg siv khoom.

Cov khaub ncaws huv si yog dab tsi?

Ib lub khaub ncaws chav huv, tseem hu ua khaub ncaws chav huv, khaub ncaws luav, lossis coveralls, yog cov khaub ncaws tshwj xeeb uas tsim los txwv tsis pub muaj cov pa phem thiab cov khoom me me rau hauv ib puag ncig chav huv. Cov chav huv yog cov chaw tswj hwm uas siv rau hauv kev tshawb fawb thiab kev lag luam, xws li kev tsim khoom semiconductor, biotechnology, tshuaj, thiab aerospace, qhov twg cov pa phem tsawg xws li hmoov av, cov kab mob hauv huab cua, thiab cov khoom me me hauv huab cua yog qhov tseem ceeb rau kev tswj hwm qhov zoo thiab kev ncaj ncees ntawm cov khoom.

Cov neeg ua haujlwm R&D hauv Lumispot Tech

Vim Li Cas Thiaj Xav Tau Cov Khaub Ncaws Huv Si:

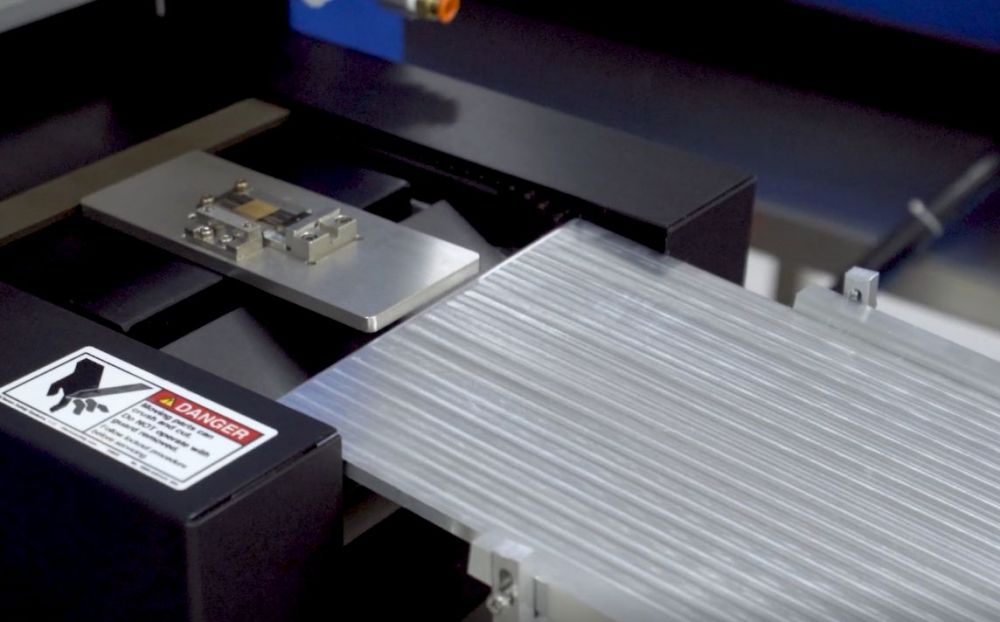

Txij li thaum nws tau tsim tsa xyoo 2010, Lumispot Tech tau siv cov kab tsim khoom tshiab, tsis muaj plua plav hauv nws qhov chaw loj 14,000-square-foot. Txhua tus neeg ua haujlwm nkag mus rau hauv thaj chaw tsim khoom yuav tsum hnav khaub ncaws huv si raws li tus qauv. Kev coj ua no qhia txog peb txoj kev tswj hwm zoo thiab kev saib xyuas rau cov txheej txheem tsim khoom.

Qhov tseem ceeb ntawm cov khaub ncaws tsis muaj plua plav hauv chaw ua haujlwm feem ntau yog pom tseeb hauv cov hauv qab no:

Chav Huv Si hauv Lumispot Tech

Txo Cov Hluav Taws Xob Static

Cov ntaub tshwj xeeb siv rau hauv cov khaub ncaws hauv chav huv feem ntau muaj cov xov hluav taws xob conductive los tiv thaiv kev sib sau ua ke ntawm hluav taws xob static, uas tuaj yeem ua rau puas tsuaj rau cov khoom siv hluav taws xob rhiab heev lossis hlawv cov khoom yooj yim kub hnyiab. Kev tsim cov khaub ncaws no ua kom ntseeg tau tias kev pheej hmoo ntawm electrostatic discharge (ESD) raug txo qis (Chubb, 2008).

Kev Tswj Xyuas Kev Ua Phem:

Cov khaub ncaws hauv chav huv yog ua los ntawm cov ntaub tshwj xeeb uas tiv thaiv kev poob ntawm cov xov lossis cov khoom me me thiab tiv taus kev tsim hluav taws xob zoo li qub uas tuaj yeem nyiam cov hmoov av. Qhov no pab tswj cov qauv kev huv huv uas xav tau hauv cov chav huv uas txawm tias cov khoom me me tuaj yeem ua rau muaj kev puas tsuaj loj rau microprocessors, microchips, cov khoom siv tshuaj, thiab lwm yam thev naus laus zis rhiab heev.

Kev Ncaj Ncees ntawm Khoom:

Hauv cov txheej txheem tsim khoom uas cov khoom lag luam muaj kev cuam tshuam loj heev rau kev ua qias tuaj ntawm ib puag ncig (xws li hauv kev tsim cov khoom siv semiconductor lossis kev tsim tshuaj), cov khaub ncaws huv si pab ua kom ntseeg tau tias cov khoom lag luam raug tsim tawm hauv ib puag ncig uas tsis muaj kev ua qias tuaj. Qhov no yog qhov tseem ceeb rau kev ua haujlwm thiab kev ntseeg tau ntawm cov khoom siv thev naus laus zis siab thiab kev nyab xeeb kev noj qab haus huv hauv cov tshuaj.

Lumispot Tech'sLaser Diode Bar ArrayCov Txheej Txheem Tsim Khoom

Kev Nyab Xeeb thiab Kev Ua Raws Cai:

Kev siv cov khaub ncaws hauv chav huv kuj raug yuam los ntawm cov qauv kev cai lij choj uas tau teeb tsa los ntawm cov koom haum xws li ISO (Lub Koom Haum Thoob Ntiaj Teb rau Kev Txheem) uas faib cov chav huv raws li tus naj npawb ntawm cov khoom me me uas tso cai rau ib lub cubic meter ntawm huab cua. Cov neeg ua haujlwm hauv chav huv yuav tsum hnav cov khaub ncaws no kom ua raws li cov qauv no thiab kom ntseeg tau tias cov khoom thiab cov neeg ua haujlwm muaj kev nyab xeeb, tshwj xeeb tshaj yog thaum kov cov khoom phom sij (Hu & Shiue, 2016).

Kev faib tawm ntawm cov khaub ncaws huv chav

Cov Qib Kev Faib Tawm: Cov khaub ncaws hauv chav huv si muaj txij li cov chav kawm qis dua xws li Chav Kawm 10000, tsim nyog rau cov chaw tsis nruj heev, mus rau cov chav kawm siab dua xws li Chav Kawm 10, uas siv rau hauv cov chaw muaj kev cuam tshuam heev vim lawv muaj peev xwm zoo dua los tswj cov khoom sib xyaw (Boone, 1998).

Chav Kawm 10 (ISO 3) Cov Khaub Ncaws:Cov khaub ncaws no tsim nyog rau cov chaw uas xav tau kev huv si siab tshaj plaws, xws li kev tsim cov tshuab laser, cov fibers optical, thiab cov optics precision. Cov khaub ncaws Class 10 zoo thaiv cov khoom me me uas loj dua 0.3 micrometers.

Chav Kawm 100 (ISO 5) Cov Khaub Ncaws:Cov khaub ncaws no yog siv rau hauv kev tsim cov khoom siv hluav taws xob, cov zaub tiaj tiaj, thiab lwm yam khoom uas xav tau kev huv si. Cov khaub ncaws Class 100 tuaj yeem thaiv cov khoom me me uas loj dua 0.5 micrometers.

Chav Kawm 1000 (ISO 6) Cov Khaub Ncaws:Cov khaub ncaws no tsim nyog rau cov chaw uas muaj qhov yuav tsum tau ua kom huv si, xws li kev tsim cov khoom siv hluav taws xob dav dav thiab cov khoom siv kho mob.

Chav Kawm 10,000 (ISO 7) Cov Khaub Ncaws:Cov khaub ncaws no siv rau hauv cov chaw ua haujlwm dav dav uas tsis tas yuav tsum tau ntxuav ntau.

Cov khaub ncaws hauv chav huv feem ntau muaj xws li lub kaus mom, lub ntsej muag npog ntsej muag, khau looj plab hlaub, cov khaub ncaws sib xws, thiab hnab looj tes, txhua yam tsim los npog cov tawv nqaij uas raug tshav ntau li ntau tau thiab tiv thaiv lub cev tib neeg, uas yog qhov chaw loj ntawm cov pa phem, los ntawm kev coj cov khoom me me mus rau hauv ib puag ncig uas tswj tau.

Siv rau hauv Optical thiab Laser Production Workshops

Hauv cov chaw xws li optics thiab laser tsim, cov khaub ncaws huv si feem ntau yuav tsum ua tau raws li cov qauv siab dua, feem ntau yog Class 100 lossis txawm tias Class 10. Qhov no ua kom muaj kev cuam tshuam tsawg kawg nkaus nrog cov khoom siv kho qhov muag thiab cov tshuab laser, uas yuav ua rau muaj teeb meem zoo thiab kev ua haujlwm (Stowers, 1999).

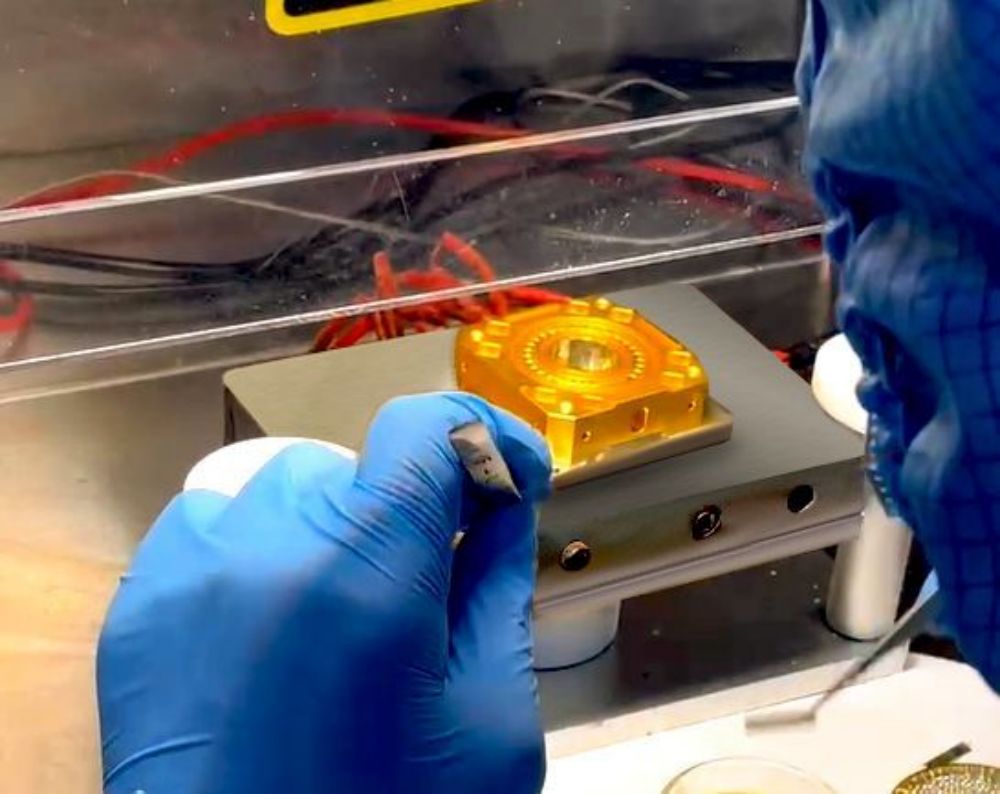

Cov neeg ua haujlwm hauv Lumispot Tech ua haujlwm rau QCWCov khoom siv laser diode annular.

Cov khaub ncaws hauv chav huv no yog ua los ntawm cov ntaub tshwj xeeb tiv thaiv hluav taws xob uas muaj cov plua plav thiab tiv taus hluav taws xob zoo heev. Kev tsim cov khaub ncaws no yog qhov tseem ceeb rau kev ua kom huv. Cov yam ntxwv xws li cov tes tsho thiab pob luj taws nruj nreem, nrog rau cov zippers uas ntev mus txog rau ntawm lub dab tshos, tau siv los ua kom muaj kev thaiv kom zoo tshaj plaws tiv thaiv cov khoom tsis huv nkag mus rau hauv thaj chaw huv.

Siv ua piv txwv

Boone, W. (1998). Kev ntsuam xyuas cov ntaub ntawm chav huv/ESD: cov txheej txheem sim thiab cov txiaj ntsig. Cov txheej txheem kev sib tham txog kev tso tawm hluav taws xob / Electrostatic. 1998 (Cat. No.98TH8347).

Stowers, I. (1999). Cov lus qhia txog kev huv ntawm lub qhov muag thiab kev txheeb xyuas kev huv. Cov txheej txheem ntawm SPIE.

Chubb, J. (2008). Kev tshawb fawb txog kev siv cov khaub ncaws hauv chav huv uas muaj neeg nyob. Phau ntawv Journal of Electrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Kev lees paub thiab kev siv cov yam ntxwv ntawm cov neeg ua haujlwm rau cov khaub ncaws siv hauv chav huv. Tsev thiab Ib puag ncig.

Lub sijhawm tshaj tawm: Plaub Hlis-24-2024