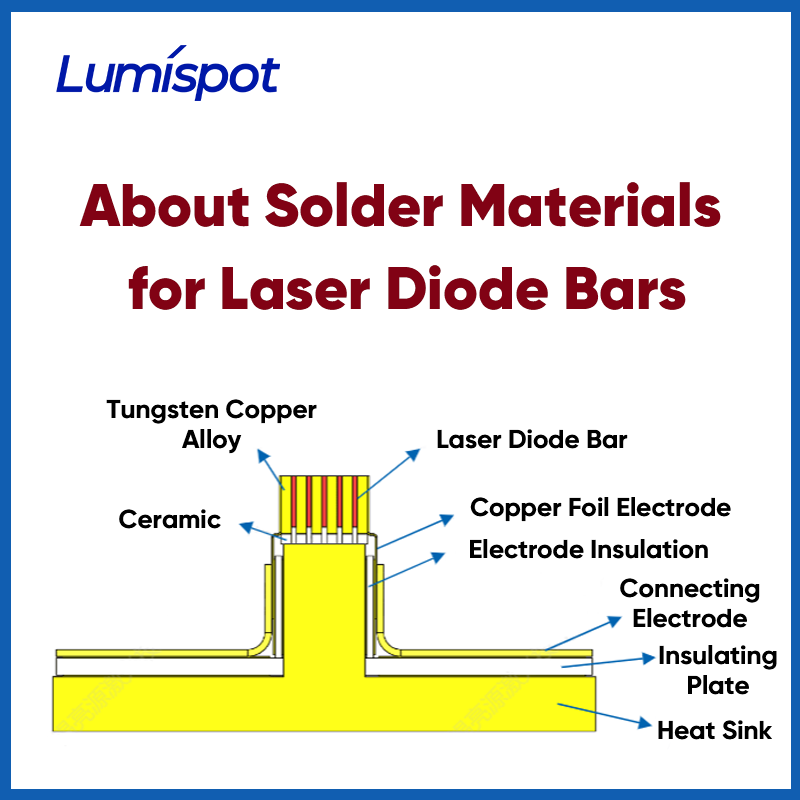

Hauv kev tsim thiab tsim cov lasers semiconductor muaj zog heev, cov laser diode bars ua lub hauv paus tseem ceeb ntawm lub teeb ci. Lawv qhov kev ua tau zoo tsis yog nyob ntawm qhov zoo ntawm cov laser chips xwb tab sis kuj tseem nyob ntawm cov txheej txheem ntim khoom. Ntawm ntau yam khoom siv hauv kev ntim khoom, cov ntaub ntawv solder ua lub luag haujlwm tseem ceeb ua qhov sib txuas thermal thiab hluav taws xob ntawm cov chip thiab lub dab dej kub.

1. Lub Luag Haujlwm ntawm Solder hauv Laser Diode Bars

Feem ntau cov laser diode bars sib xyaw ua ke ntau lub emitters, ua rau muaj zog ntau thiab cov kev cai tswj hwm thermal nruj. Yuav kom ua tiav kev tshem tawm cua sov zoo thiab kev ruaj khov ntawm cov qauv, cov ntaub ntawv solder yuav tsum ua tau raws li cov qauv hauv qab no:

① Kev ua tau zoo ntawm cov cua sov:

Xyuas kom meej tias cov cua sov hloov pauv tau zoo los ntawm lub laser chip.

② Kev ntub dej zoo:

Muab kev sib txuas ruaj khov ntawm lub chip thiab lub substrate.

③ Qhov chaw yaj uas tsim nyog:

Tiv thaiv kev rov ua dua lossis kev puas tsuaj thaum lub sijhawm ua tiav lossis kev ua haujlwm tom qab.

④ Cov coefficient sib xws ntawm kev nthuav dav thermal (CTE):

Txo qhov kev ntxhov siab thermal ntawm lub nti.

⑤ Kev tiv thaiv kev qaug zog zoo heev:

Ua kom lub neej ua haujlwm ntawm lub cuab yeej ntev dua.

2. Hom Kev Sib Txuas Lus Rau Laser Bar Ntim Khoom

Cov hauv qab no yog peb hom khoom siv solder uas feem ntau siv rau hauv kev ntim khoom ntawm laser diode bars:

①Kub-Tin Alloy (AuSn)

Cov Khoom:

Muaj pes tsawg leeg Eutectic ntawm 80Au/20Sn nrog lub melting point ntawm 280 ° C; thermal conductivity siab thiab lub zog kho tshuab.

Cov txiaj ntsig:

Kev ruaj khov zoo heev thaum kub thiab txias, lub neej ntev thaum tshav kub kub, tsis muaj kuab paug organic, kev ntseeg siab siab

Cov ntawv thov:

Cov tshuab laser rau tub rog, aerospace, thiab kev lag luam siab heev.

②Indium Ntshiab (Hauv)

Cov Khoom:

Melting point ntawm 157 ° C; mos thiab yooj yim heev.

Cov txiaj ntsig:

Kev ua haujlwm kub zoo tshaj plaws, kev ntxhov siab tsawg ntawm lub nti, zoo tagnrho rau kev tiv thaiv cov qauv tawg yooj yim, tsim nyog rau qhov yuav tsum tau ua kom sov qis

Cov Kev Txwv:

Yooj yim rau oxidation; xav tau huab cua inert thaum lub sijhawm ua tiav, qis dua lub zog kho tshuab; tsis zoo tagnrho rau cov ntawv thov siab-load

③Cov Txheej Txheem Sib Xyaws Ua Ke (piv txwv li, AuSn + Hauv)

Qauv:

Feem ntau, AuSn siv rau hauv qab lub nti rau kev txuas ruaj khov, thaum In siv rau sab saum toj rau kev txhim kho thermal buffering.

Cov txiaj ntsig:

Ua ke kev ntseeg siab nrog kev txo kev ntxhov siab, txhim kho kev ruaj khov ntawm cov ntim khoom, hloov kho tau zoo rau ntau qhov chaw ua haujlwm sib txawv

3. Kev cuam tshuam ntawm qhov zoo ntawm cov khoom siv vuam rau kev ua haujlwm ntawm lub cuab yeej

Kev xaiv cov khoom siv solder thiab kev tswj cov txheej txheem cuam tshuam rau kev ua haujlwm electro-optical thiab kev ruaj khov mus sij hawm ntev ntawm cov khoom siv laser:

| Qhov Cuam Tshuam ntawm Solder | Kev Cuam Tshuam Rau Lub Cuab Yeej |

| Kev sib npaug ntawm cov txheej txheem solder | Cuam tshuam rau kev faib cua sov thiab lub zog kho qhov muag sib xws |

| Qhov piv tsis muaj dab tsi | Cov voids siab dua ua rau muaj kev tiv thaiv thermal ntau ntxiv thiab qhov kub hnyiab hauv zos |

| Kev huv ntawm cov hlau nplaum | Kev cuam tshuam rau kev ruaj khov ntawm kev yaj thiab kev sib kis ntawm cov hlau |

| Kev ntub dej ntawm qhov sib txuas | Txheeb xyuas lub zog sib txuas thiab qhov sib txuas thermal conductivity |

Nyob rau hauv kev ua haujlwm tas mus li ntawm lub zog siab, txawm tias qhov tsis zoo me me hauv kev vuam tuaj yeem ua rau muaj cua sov ntau dhau, ua rau kev ua haujlwm poob qis lossis lub cuab yeej ua tsis tiav. Yog li ntawd, kev xaiv cov vuam zoo thiab kev siv cov txheej txheem vuam kom raug yog qhov tseem ceeb rau kev ua tiav cov khoom ntim laser uas ntseeg tau siab.

4. Cov Qauv thiab Kev Txhim Kho Yav Tom Ntej

Raws li cov thev naus laus zis laser txuas ntxiv mus rau hauv kev ua lag luam, kev phais mob, LiDAR, thiab lwm yam teb, cov ntaub ntawv solder rau laser ntim khoom tab tom hloov pauv mus rau hauv cov lus qhia hauv qab no:

①Kev siv vuam kub tsawg:

Rau kev koom ua ke nrog cov ntaub ntawv thermally rhiab heev

②Cov hlau tsis muaj txhuas:

Ua kom tau raws li RoHS thiab lwm yam kev cai ib puag ncig

③Cov ntaub ntawv sib txuas thermal ua tau zoo (TIM):

Txhawm rau kom txo qhov kev tiv thaiv thermal ntxiv

④Cov txheej txheem micro-soldering:

Txhawb kev ua kom me me thiab kev sib koom ua ke ntawm cov khoom siv high-density

5. Xaus Lus

Txawm hais tias muaj me me xwb los, cov khoom siv solder yog cov khoom sib txuas tseem ceeb uas ua kom muaj kev ua tau zoo thiab kev ntseeg tau ntawm cov khoom siv laser muaj zog heev. Hauv kev ntim khoom ntawm cov laser diode bars, kev xaiv cov solder zoo thiab kev ua kom zoo dua ntawm cov txheej txheem sib txuas yog qhov tseem ceeb rau kev ua haujlwm ruaj khov mus sij hawm ntev.

6. Txog Peb

Lumispot cog lus tias yuav muab cov khoom siv laser thiab cov kev daws teeb meem ntim khoom uas zoo thiab txhim khu kev qha rau cov neeg siv khoom. Nrog kev paub dhau los hauv kev xaiv cov khoom siv solder, kev tsim qauv tswj thermal, thiab kev ntsuam xyuas kev ntseeg siab, peb ntseeg tias txhua qhov kev ua kom zoo nkauj hauv kev nthuav dav yuav ua rau muaj kev ua tau zoo tshaj plaws. Yog xav paub ntxiv txog cov thev naus laus zis ntim khoom laser muaj zog, thov hu rau peb.

Lub sijhawm tshaj tawm: Lub Xya Hli-07-2025