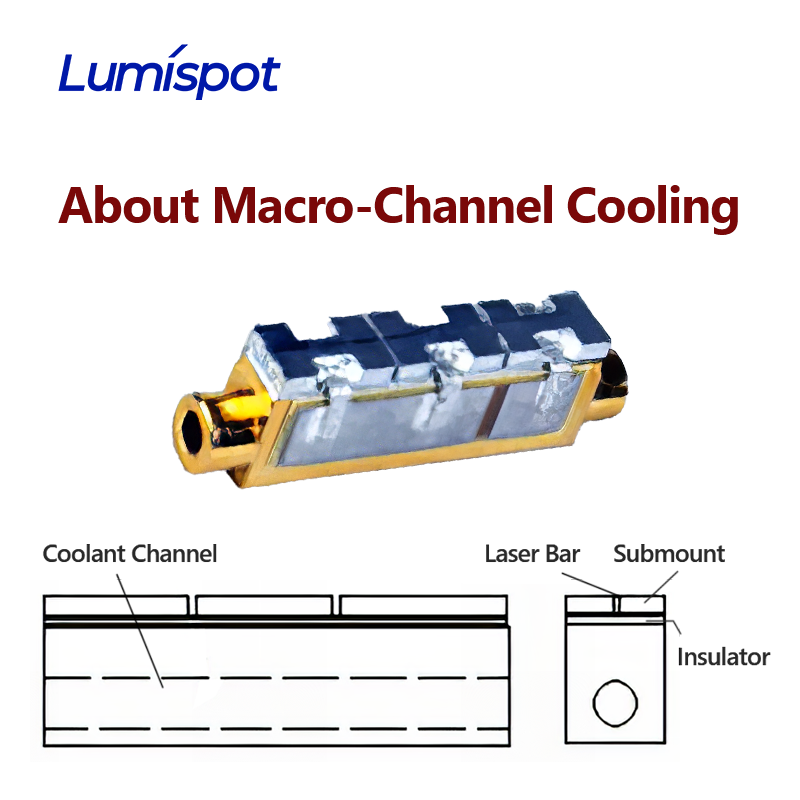

Hauv cov ntawv thov xws li cov lasers muaj zog heev, cov khoom siv hluav taws xob fais fab, thiab cov kab ke sib txuas lus, kev siv hluav taws xob ntau ntxiv thiab kev sib koom ua ke tau ua rau kev tswj hwm thermal ua qhov tseem ceeb uas cuam tshuam rau kev ua haujlwm ntawm cov khoom, lub neej ntev, thiab kev ntseeg siab. Nrog rau kev txias micro-channel,kev txias macro-channeltau tshwm sim los ua ib qho kev daws teeb meem ua kua txias. Nws cov qauv yooj yim dua, tus nqi qis dua, thiab kev saib xyuas yooj yim dua ua rau nws tsim nyog rau ntau qhov xwm txheej kev lag luam.

1. Macro-Channel Cooling Yog Dab Tsi?

Kev txias macro-channel suav nrog kev siv cov channel loj dua ntawm cov dej txias (feem ntau yog nyob rau hauv millimeter ntau yam) uas tau tsim rau hauv cov phaj txias lossis cov modules. Cov channel no coj cov kua dej txias - feem ntau yog dej deionized, cov kua glycol-based, lossis lwm yam dej txias hauv kev lag luam - los ntawm lub kaw lus kom tshem tawm cov cua sov tsim thaum lub sijhawm ua haujlwm ntawm lub cuab yeej. Thaum koom ua ke nrog lub voj voog dej txias, qhov kev teeb tsa no ua rau muaj kev tswj hwm thermal tas mus li thiab ua haujlwm tau zoo.

2. Macro-Channel piv rau Micro-Channel: Qhov Sib Txawv Tseem Ceeb

| Feature | Macro-Channel Txias | Micro-Channel Txias |

| Qhov Loj ntawm Txoj Kev | Qhov ntsuas millimeter (1mm txog ntau mm) | Micrometer-scale (kaum txog pua pua μm) |

| Kev Ua Khoom Siv Nyuaj | Tsawg heev | Yuav tsum tau ua kom raug qhov tseeb |

| Kev Tiv Thaiv Dej | Qis, kua dej ntws tau yooj yim | Siab, xav tau lub twj tso kua mis siab dua |

| Kev Ua Haujlwm Kub Pauv | Nruab nrab, tsim nyog rau qhov kub nruab nrab | Siab, zoo tagnrho rau kev ua kom sov heev |

| Tus nqi | Qis dua | Siab dua |

| Daim Ntawv Thov Ib Txwm Muaj | Cov cua sov nruab nrab mus rau qis, cov txheej txheem kev ntseeg siab siab | Muaj zog ntau, cov chaw kub hauv zos |

3. Cov txiaj ntsig ntawm Macro-Channel Cooling

Txawm hais tias nws cov thermal efficiency qis dua li cov kev daws teeb meem micro-channel, macro-channel txias muaj ntau qhov txiaj ntsig tseem ceeb:

①Kev ntseeg siab siab:

Cov kav dej dav dua tsis yooj yim txhaws, muab kev ruaj khov zoo heev rau lub sijhawm ntev - zoo tagnrho rau kev ua haujlwm hauv kev lag luam tas mus li.

②Cov nqi tsim khoom qis dua:

Cov qauv yooj yim dua thiab ntau yam kev xaiv tsim khoom ua rau nws tsim nyog rau kev tsim khoom loj.

③Yooj yim ntawm kev saib xyuas:

Lub sijhawm ntxuav ntev, cov nqi kho tsis kim, thiab qhov yuav tsum tau ua kom cov dej txias huv tsis nruj heev.

④Muaj peev xwm txias txaus:

Rau cov khoom siv uas muaj cua sov nruab nrab, kev txias macro-channel zoo tswj tau qhov kub thiab txias zoo tshaj plaws thiab ua kom lub cuab yeej siv tau ntev dua.

4. Cov Xwm Txheej Thov

Macro-channel txias yog siv dav hauv cov cheeb tsam hauv qab no:

①Cov qauv laser:

Tshwj xeeb tshaj yog rau nruab nrab-rau qis-zog lossis CW-hom lasers, macro-channel systems tuaj yeem yooj yim tswj hwm cov thermal load.

②Cov khoom siv hluav taws xob fais fab:

Xws li cov rectifiers, DC-DC converters, thiab IGBT modules.

③Cov amplifiers fais fab hauv kev sib txuas lus thiab radar systems:

Zoo tagnrho rau cov chaw nyuaj uas xav tau kev ua haujlwm ntev thiab ruaj khov.

④Cov tshuab cua txias hauv cov khoom siv kho mob thiab kev lag luam:

Xws li cov khoom siv kho mob semiconductor laser, cov tshuab laser marking, thiab lwm yam.

5. Cov Kev Xav Txog Kev Tsim Qauv Tseem Ceeb rau Macro-Channel Cooling

Ib qho kev daws teeb meem txias macro-channel uas ua tiav yuav tsum tau ua tib zoo saib xyuas cov hauv qab no:

①Kev teeb tsa channel:

Yuav tsum tau ua kom zoo dua raws li qhov faib tawm ntawm qhov chaw cua sov ntawm lub cuab yeej kom ua tiav qhov txias sib xws.

②Kev xaiv cov khoom siv:

Cov tooj liab, cov hlau tsis xeb, lossis cov hlau txhuas feem ntau yog siv rau lawv cov thermal conductivity siab thiab tiv taus corrosion.

③Tus nqi ntws thiab lub twj tso kua mis sib xws:

Kev tsim qauv kom zoo ntawm qhov ceev ntawm cov kua dej thiab cov dej txias ntws ua kom muaj kev sib pauv cua sov zoo thiab kev ruaj khov ntawm lub kaw lus.

④Cov interfaces txheem:

Ua kom yooj yim rau kev koom ua ke rau hauv cov khoom siv lossis cov modules ntawm cov neeg siv khoom.

6. Xaus Lus

Kev txias macro-channel tseem ua lub luag haujlwm tseem ceeb hauv kev siv hauv kev lag luam vim nws yooj yim, kev ntseeg siab, thiab yooj yim rau kev saib xyuas. Nws yog ib qho kev daws teeb meem pheej yig thiab txhim khu kev qha, tshwj xeeb tshaj yog nyob rau hauv cov kab ke nrog qhov nruab nrab mus rau qis thermal densities. Raws li kev tsim khoom siv hloov zuj zus, cov kev daws teeb meem macro-channel kuj tseem tab tom nce qib mus rau kev sib koom ua ke siab dua thiab kev hloov pauv tau zoo dua.

7. Txog Peb

Lumispotmuaj kev txawj ntse ntau hauv kev daws teeb meem kev tswj cua sov macro-channel thiab micro-channel. Peb muab cov modules txias tshwj xeeb rau lasers, optoelectronic devices, fais fab electronics, thiab ntau ntxiv. Peb lub hom phiaj mus dhau qhov kev ua tau zoo thermal - peb muab qhov tseem ceeb rau kev koom ua ke ntawm lub kaw lus thiab kev ntseeg siab mus sij hawm ntev, lub hom phiaj yog xa cov kab ke ua haujlwm siab, pheej yig.

Xav tiv tauj peb kom paub ntau ntxiv txog kev daws teeb meem txias macro-channel thiab micro-channel uas tsim los rau koj cov kev xav tau ntawm daim ntawv thov!

Lub sijhawm tshaj tawm: Lub Rau Hli-17-2025