Sau npe rau peb cov social media kom tau txais cov ntawv tshaj tawm sai

Kev Taw Qhia Txog Laser Processing hauv Kev Tsim Khoom

Cov thev naus laus zis ua laser tau muaj kev loj hlob sai thiab siv dav hauv ntau qhov chaw, xws li aerospace, automotive, electronics, thiab lwm yam. Nws ua lub luag haujlwm tseem ceeb hauv kev txhim kho cov khoom zoo, kev tsim khoom ua haujlwm, thiab kev siv tshuab, thaum txo cov pa phem thiab kev siv khoom (Gong, 2012).

Kev Ua Laser hauv Cov Khoom Siv Hlau thiab Cov Khoom Uas Tsis Yog Hlau

Kev siv laser ua cov txheej txheem tseem ceeb hauv kaum xyoo dhau los yog nyob rau hauv cov khoom siv hlau, suav nrog kev txiav, vuam, thiab cladding. Txawm li cas los xij, daim teb no tab tom nthuav dav mus rau cov khoom siv tsis yog hlau xws li textiles, iav, yas, polymers, thiab ceramics. Txhua yam ntawm cov ntaub ntawv no qhib lub sijhawm hauv ntau yam lag luam, txawm hais tias lawv twb muaj cov txheej txheem ua tiav lawm (Yumoto et al., 2017).

Cov Kev Cov nyom thiab Kev Tsim Kho Tshiab hauv Laser Processing ntawm Iav

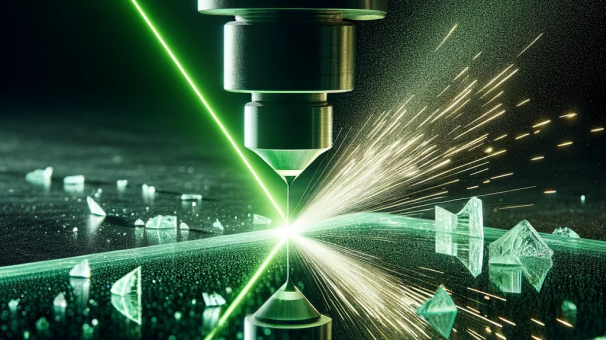

Iav, nrog nws cov ntawv thov dav hauv kev lag luam xws li tsheb, kev tsim kho, thiab khoom siv hluav taws xob, sawv cev rau thaj chaw tseem ceeb rau kev ua laser. Cov txheej txheem txiav iav ib txwm muaj, uas siv cov cuab yeej hlau nplaum lossis pob zeb diamond, raug txwv los ntawm kev ua haujlwm tsawg thiab cov npoo ntxhib. Qhov sib piv, kev txiav laser muab lwm txoj hauv kev ua haujlwm zoo dua thiab meej dua. Qhov no pom tseeb tshwj xeeb hauv kev lag luam xws li kev tsim khoom siv xov tooj ntawm tes, qhov twg kev txiav laser siv rau lub koob yees duab lens npog thiab cov ntxaij vab tshaus loj (Ding et al., 2019).

Kev Ua Haujlwm Laser ntawm Cov Hom Iav Muaj Nqis Siab

Cov iav sib txawv, xws li iav kho qhov muag, iav quartz, thiab iav sapphire, muaj teeb meem tshwj xeeb vim lawv qhov xwm txheej brittle. Txawm li cas los xij, cov txheej txheem laser siab heev xws li femtosecond laser etching tau ua rau muaj kev ua tiav ntawm cov ntaub ntawv no (Sun & Flores, 2010).

Kev cuam tshuam ntawm Wavelength rau Laser Technological Processes

Qhov wavelength ntawm lub laser muaj feem cuam tshuam rau cov txheej txheem, tshwj xeeb tshaj yog rau cov ntaub ntawv xws li cov hlau ua vaj tse. Cov lasers emitting hauv ultraviolet, pom, ze thiab deb infrared cheeb tsam tau raug soj ntsuam rau lawv lub zog ceev rau melting thiab evaporation (Lazov, Angelov, & Teirumnieks, 2019).

Cov Ntawv Thov Sib Txawv Raws Li Wavelengths

Qhov kev xaiv ntawm laser wavelength tsis yog random tab sis nws nyob ntawm cov khoom siv thiab qhov tshwm sim xav tau. Piv txwv li, UV lasers (nrog wavelengths luv dua) zoo heev rau kev txiav thiab micromachining, vim lawv tuaj yeem tsim cov ntsiab lus zoo dua. Qhov no ua rau lawv zoo tagnrho rau kev lag luam semiconductor thiab microelectronics. Hauv kev sib piv, infrared lasers ua haujlwm tau zoo dua rau kev ua cov khoom tuab dua vim lawv muaj peev xwm nkag mus tob dua, ua rau lawv haum rau cov ntawv thov kev lag luam hnyav. (Majumdar & Manna, 2013). Ib yam li ntawd, cov lasers ntsuab, feem ntau ua haujlwm ntawm wavelength ntawm 532 nm, nrhiav lawv qhov chaw nyob hauv cov ntawv thov uas xav tau qhov tseeb siab nrog qhov cuam tshuam thermal tsawg kawg nkaus. Lawv muaj txiaj ntsig zoo hauv microelectronics rau cov haujlwm xws li circuit patterning, hauv kev siv kho mob rau cov txheej txheem xws li photocoagulation, thiab hauv lub zog rov ua dua tshiab rau kev tsim lub hnub ci cell. Cov lasers ntsuab 'wavelength tshwj xeeb kuj ua rau lawv haum rau kev cim thiab txiav ntau yam khoom siv, suav nrog cov yas thiab hlau, qhov twg qhov sib piv siab thiab qhov puas tsuaj tsawg kawg nkaus ntawm qhov chaw xav tau. Qhov kev hloov pauv ntawm cov lasers ntsuab no qhia txog qhov tseem ceeb ntawm kev xaiv wavelength hauv laser technology, ua kom ntseeg tau tias muaj txiaj ntsig zoo tshaj plaws rau cov ntaub ntawv tshwj xeeb thiab cov ntawv thov.

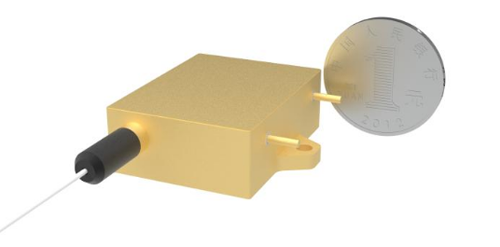

Lub525nm ntsuab laseryog ib hom tshuab laser tshwj xeeb uas tau piav qhia los ntawm nws qhov kev tso tawm lub teeb ntsuab sib txawv ntawm qhov ntev ntawm 525 nanometers. Cov lasers ntsuab ntawm qhov ntev no nrhiav tau cov ntawv thov hauv retinal photocoagulation, qhov twg lawv lub zog siab thiab qhov tseeb yog qhov zoo. Lawv kuj tseem muaj peev xwm pab tau hauv kev ua cov khoom siv, tshwj xeeb tshaj yog nyob rau hauv cov teb uas xav tau kev ua tiav thermal meej thiab tsawg kawg nkaus..Kev tsim cov diodes laser ntsuab ntawm c-plane GaN substrate mus rau qhov ntev dua ntawm 524–532 nm cim qhov kev nce qib tseem ceeb hauv kev siv tshuab laser. Qhov kev txhim kho no yog qhov tseem ceeb rau cov ntawv thov uas xav tau cov yam ntxwv tshwj xeeb ntawm qhov ntev.

Cov Qhov Chaw Laser Txuas Ntxiv Mus Thiab Modelocked

Cov teeb ci ntsa iab tas mus li (CW) thiab cov teeb ci uas muaj cov qauv ze ze (CW) ntawm ntau qhov ntev xws li ze infrared (NIR) ntawm 1064 nm, ntsuab ntawm 532 nm, thiab ultraviolet (UV) ntawm 355 nm raug txiav txim siab rau cov roj teeb hnub ci uas siv laser doping. Cov ntev ntev sib txawv muaj feem cuam tshuam rau kev hloov pauv thiab kev ua haujlwm ntawm kev tsim khoom (Patel et al., 2011).

Excimer Lasers rau Cov Khoom Siv Dav Dav

Cov lasers Excimer, ua haujlwm ntawm UV wavelength, yog qhov tsim nyog rau kev ua cov ntaub ntawv dav dav xws li iav thiab carbon fiber-reinforced polymer (CFRP), muab qhov tseeb siab thiab qhov cuam tshuam thermal tsawg kawg nkaus (Kobayashi et al., 2017).

Nd: YAG Lasers rau Kev Siv Hauv Kev Lag Luam

Nd:YAG lasers, nrog lawv qhov kev hloov pauv tau raws li qhov wavelength tuning, siv rau ntau yam kev siv. Lawv lub peev xwm ua haujlwm ntawm ob qho tib si 1064 nm thiab 532 nm tso cai rau kev ywj pheej hauv kev ua cov ntaub ntawv sib txawv. Piv txwv li, 1064 nm wavelength yog qhov zoo tagnrho rau kev kos duab tob rau ntawm cov hlau, thaum 532 nm wavelength muab cov duab kos zoo rau ntawm cov yas thiab cov hlau coated. (Moon et al., 1999).

→ Cov Khoom Sib Xws:CW Diode-pumped solid-state laser nrog 1064nm wavelength

Kev Vuam Laser Fiber Ntau Zog Siab

Cov lasers nrog cov wavelengths ze li ntawm 1000 nm, muaj lub teeb zoo thiab lub zog siab, yog siv rau hauv kev vuam laser keyhole rau cov hlau. Cov lasers no ua rau cov khoom siv vaporize thiab yaj tau zoo, tsim cov vuam zoo (Salminen, Piili, & Purtonen, 2010).

Kev koom ua ke ntawm Laser Processing nrog lwm yam Technologies

Kev koom ua ke ntawm kev ua laser nrog lwm cov thev naus laus zis tsim khoom, xws li cladding thiab milling, tau ua rau muaj cov txheej txheem tsim khoom zoo dua thiab ntau yam. Qhov kev koom ua ke no muaj txiaj ntsig zoo hauv kev lag luam xws li kev tsim cov cuab yeej thiab pwm thiab kho cav (Nowotny et al., 2010).

Kev Ua Laser hauv Cov Teb Tshiab

Daim ntawv thov ntawm cov thev naus laus zis laser nthuav dav mus rau cov teb tshiab xws li semiconductor, zaub, thiab cov lag luam zaj duab xis nyias, muab cov peev xwm tshiab thiab txhim kho cov khoom siv, kev ua haujlwm ntawm cov khoom, thiab kev ua haujlwm ntawm cov cuab yeej (Hwang et al., 2022).

Cov Qauv Yav Tom Ntej hauv Kev Ua Laser

Kev txhim kho yav tom ntej hauv kev siv tshuab laser processing yog tsom mus rau cov txheej txheem tsim khoom tshiab, txhim kho cov khoom zoo, kev tsim cov khoom sib xyaw ua ke ntawm ntau yam khoom siv thiab txhim kho cov txiaj ntsig kev lag luam thiab cov txheej txheem. Qhov no suav nrog kev tsim khoom sai sai ntawm cov qauv nrog kev tswj hwm porosity, hybrid welding, thiab laser profile txiav ntawm cov ntawv hlau (Kukreja et al., 2013).

Kev siv tshuab ua laser, nrog nws cov kev siv sib txawv thiab kev tsim kho tshiab tas mus li, tab tom tsim lub neej yav tom ntej ntawm kev tsim khoom thiab kev ua cov khoom siv. Nws qhov kev ua tau ntau yam thiab kev ua kom raug ua rau nws yog ib qho cuab yeej tseem ceeb hauv ntau yam lag luam, thawb cov ciam teb ntawm cov txheej txheem tsim khoom ib txwm muaj.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). TXOJ KEV KWV YEES UA NTEJ TXOG LUB HWJ CHIM HEEV HAUV LASER TECHNOLOGICAL PROCESSES.IB PUAG NCIG. TXUJ CI. COV PEJ XEEM. Cov Txheej Txheem ntawm Lub Rooj Sib Tham Thoob Ntiaj Teb Txog Kev Tshawb Fawb thiab Kev Ua Haujlwm. Txuas

Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Kev Tsim Khoom Siv Laser Doping Selective Emitter Solar Cells Siv 532nm Continuous Wave (CW) thiab Modelocked Quasi-CW Laser Sources.Txuas

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV siab zog lasers ua rau iav thiab CFRP.Txuas

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Kev ua haujlwm zoo ntawm lub zog intracavity ob npaug los ntawm lub diode diffusive reflector-type diode side-pumped Nd:YAG laser siv lub KTP crystal.Txuas

Salminen, A., Piili, H., & Purtonen, T. (2010). Cov yam ntxwv ntawm lub zog fiber ntau laser vuam.Cov Txheej Txheem ntawm Lub Tsev Kawm Ntawv ntawm Cov Kws Ua Haujlwm Mechanical, Ntu C: Phau Ntawv Xov Xwm ntawm Kev Tshawb Fawb Txog Kev Ua Haujlwm Mechanical, 224, 1019-1029.Txuas

Majumdar, J., & Manna, I. (2013). Kev Taw Qhia Txog Kev Tsim Khoom Siv Laser Pab.Txuas

Gong, S. (2012). Kev tshawb nrhiav thiab kev siv cov thev naus laus zis ua laser siab heev.Txuas

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Kev Tsim Kho Lub Txaj Ntsuas Kev Tsim Khoom Siv Laser thiab Lub Chaw Khaws Ntaub Ntawv rau Kev Ua Khoom Siv Laser.Kev Tshuaj Xyuas Txog Kev Tsim Kho Laser, 45, 565-570.Txuas

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Advances nyob rau hauv-situ saib xyuas tshuab rau laser ua.SCIENTIA SINICA Physica, Mechanica & Astronomica. Txuas

Sun, H., & Flores, K. (2010). Kev Tshawb Fawb Txog Microstructural ntawm Laser-Processed Zr-Based Bulk Metallic Iav.Kev Lag Luam Hlau thiab Cov Khoom Siv A. Txuas

Nowotny, S., Muenster, R., Scharek, S., & Beyer, E. (2010). Lub cell laser sib xyaw ua ke rau kev sib xyaw ua ke ntawm laser cladding thiab milling.Kev Sib Dhos Ua Haujlwm, 30(1), 36-38.Txuas

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Cov txheej txheem ua cov khoom siv laser tshiab rau kev siv hauv kev lag luam yav tom ntej.Txuas

Hwang, E., Choi, J., & Hong, S. (2022). Cov txheej txheem nqus tsev uas siv laser pab rau kev tsim khoom uas muaj qhov tseeb heev, muaj txiaj ntsig zoo.Nanoscale. Txuas

Lub sijhawm tshaj tawm: Lub Ib Hlis-18-2024