Raws li cov thev naus laus zis laser muaj zog siab txuas ntxiv mus sai sai, Laser Diode Bars (LDBs) tau siv dav hauv kev ua lag luam, kev phais mob, LiDAR, thiab kev tshawb fawb vim lawv lub zog siab thiab qhov ci ntsa iab. Txawm li cas los xij, nrog rau kev sib koom ua ke thiab kev ua haujlwm tam sim no ntawm cov chips laser, cov teeb meem kev tswj hwm thermal tau dhau los ua qhov tseem ceeb dua - cuam tshuam ncaj qha rau kev ua haujlwm ruaj khov thiab lub neej ntawm lub laser.

Ntawm ntau yam tswv yim tswj kev kub, Kev Sib Txuas Lus Txias yog ib qho ntawm cov txheej txheem tseem ceeb tshaj plaws thiab dav dav hauv kev ntim khoom laser diode bar, ua tsaug rau nws cov qauv yooj yim thiab kev ua haujlwm thermal siab. Tsab xov xwm no tshawb nrhiav cov ntsiab cai, cov kev xav tseem ceeb ntawm kev tsim qauv, kev xaiv cov khoom siv, thiab cov qauv yav tom ntej ntawm "kev nyob twj ywm" no rau kev tswj kev kub.

1. Cov Ntsiab Cai ntawm Kev Sib Txuas Lus Txias

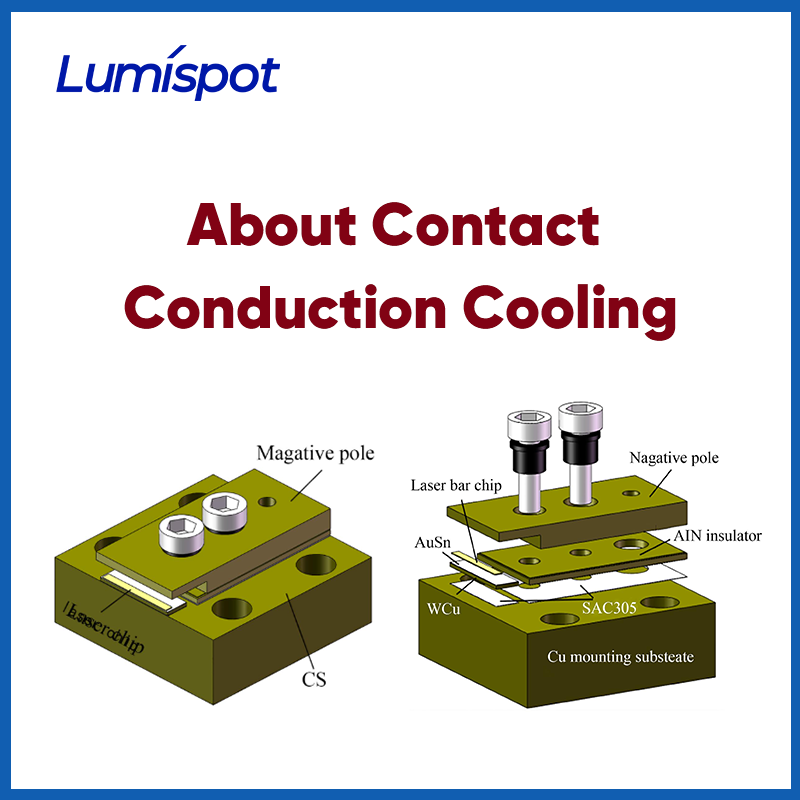

Raws li lub npe qhia, kev sib cuag conduction txias ua haujlwm los ntawm kev tsim kom muaj kev sib cuag ncaj qha ntawm lub laser chip thiab lub cua sov, ua rau muaj kev hloov pauv cua sov zoo los ntawm cov khoom siv thermal conductivity siab thiab sai dissipation rau ib puag ncig sab nraud.

①The HnojPath:

Hauv ib lub laser diode bar, txoj kev cua sov yog raws li nram no:

Chip → Solder Txheej → Submount (piv txwv li, tooj liab lossis ceramic) → TEC (Thermoelectric Cooler) lossis Heat Sink → Ambient Environment

②Nta:

Txoj kev txias no muaj cov yam ntxwv:

Kev ntws cua sov thiab txoj kev thermal luv luv, ua kom txo qhov kub ntawm qhov sib tshuam; Kev tsim qauv me me, haum rau cov ntim khoom me me; Kev coj ua tsis siv neeg, tsis tas yuav muaj cov voj voog txias nyuaj.

2. Cov Kev Xav Tseem Ceeb rau Kev Tsim Qauv rau Kev Ua Haujlwm Thermal

Yuav kom ntseeg tau tias kev sib cuag txias zoo, cov hauv qab no yuav tsum tau ua tib zoo saib xyuas thaum tsim lub cuab yeej:

① Kev Tiv Thaiv Thermal ntawm Qhov Sib Txuas Solder

Qhov thermal conductivity ntawm cov txheej solder ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv thermal tag nrho. Yuav tsum siv cov hlau uas muaj high-conductivity xws li AuSn alloy lossis indium ntshiab, thiab yuav tsum tswj cov tuab thiab kev sib xws ntawm cov txheej solder kom txo qis cov teeb meem thermal.

② Kev Xaiv Khoom Siv Submount

Cov ntaub ntawv submount feem ntau muaj xws li:

Tooj Liab (Cu): Kev ua tau zoo ntawm cov cua sov, pheej yig;

Tungsten Tooj Liab (WCu)/Molybdenum Tooj Liab (MoCu): Zoo dua CTE phim nrog cov chips, muab ob qho tib si lub zog thiab conductivity;

Aluminium Nitride (AlN): Kev rwb thaiv hluav taws xob zoo heev, tsim nyog rau cov ntawv thov hluav taws xob siab.

③ Kev Sib Cuag Nto Zoo

Qhov roughness ntawm qhov chaw, flatness, thiab wettability cuam tshuam ncaj qha rau qhov ua tau zoo ntawm kev hloov pauv cua sov. Kev txhuam thiab kub plating feem ntau yog siv los txhim kho kev ua haujlwm thermal contact.

④ Txo Txoj Kev Thermal

Tus qauv tsim yuav tsum tsom mus rau kev ua kom txoj kev cua sov luv dua ntawm lub chip thiab lub dab dej cua sov. Tsis txhob muab cov txheej nruab nrab uas tsis tsim nyog los txhim kho kev ua haujlwm ntawm kev tso cua sov.

3. Cov Lus Qhia Txog Kev Loj Hlob Yav Tom Ntej

Nrog rau qhov sib txawv ntawm kev ua kom me me thiab lub zog ceev dua, kev siv tshuab txias hu rau conduction tau hloov zuj zus mus rau hauv cov lus qhia hauv qab no:

① Cov TIMs Sib Xyaws Ntau Txheej

Ua ke cov hlau thermal conduction nrog flexible buffering kom txo qhov interface tsis kam thiab txhim kho thermal cycling durability.

② Kev Ntim Khoom Siv Kub Sib Xyaws

Tsim cov submounts thiab cov cua sov ua ib qho kev sib koom ua ke los txo cov kev sib cuag thiab ua kom muaj kev hloov pauv cua sov zoo dua.

③ Kev Txhim Kho Cov Qauv Bionic

Siv cov nplaim microstructured uas ua raws li cov txheej txheem ntuj tsim ntawm kev tso cua sov - xws li "kev coj ua zoo li ntoo" lossis "cov qauv zoo li nplai" - los txhim kho kev ua haujlwm thermal.

④ Kev Tswj Xyuas Thermal Txawj Ntse

Kev suav nrog cov ntsuas kub thiab kev tswj hwm lub zog dynamic rau kev tswj hwm thermal adaptive, txuas ntxiv lub neej ua haujlwm ntawm lub cuab yeej.

4. Xaus Lus

Rau cov laser diode bars uas muaj zog heev, kev tswj cua sov tsis yog ib qho kev sib tw xwb - nws yog lub hauv paus tseem ceeb rau kev ntseeg tau. Kev sib cuag cua txias, nrog nws cov yam ntxwv ua haujlwm tau zoo, laus zuj zus, thiab tsim nyog tus nqi, tseem yog ib qho ntawm cov kev daws teeb meem tseem ceeb rau kev tshem tawm cua sov niaj hnub no.

5. Txog Peb

Ntawm Lumispot, peb coj kev txawj ntse tob hauv kev ntim khoom laser diode, kev ntsuam xyuas kev tswj hwm thermal, thiab kev xaiv cov khoom siv. Peb lub hom phiaj yog muab cov kev daws teeb meem laser ua haujlwm siab, lub neej ntev uas tsim los rau koj cov kev xav tau ntawm daim ntawv thov. Yog tias koj xav paub ntau ntxiv, peb zoo siab tos txais koj los tiv tauj peb pab neeg.

Lub sijhawm tshaj tawm: Lub Rau Hli-23-2025